Coldface: the HORECA sector’s best ally for camera control

Eliwell Coldfaces: innovation and efficiency in cold room control and refrigeration

With the arrival of summer and the increase of tourism in Spain, the HORECA sector (Hotels, Restaurants and Cafeterias) faces the great challenge of maintaining food quality and freshness. Failure in cold storage can have serious consequences for the business

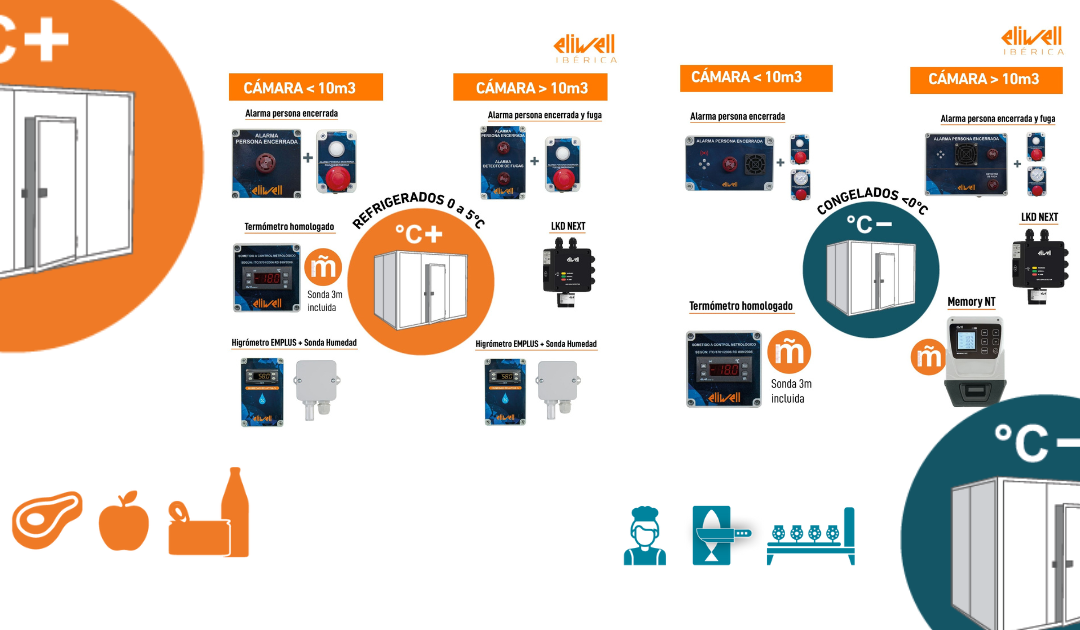

Eliwell's Coldface series, models 300NT, 500NT and 5000NT, offers advanced solutions for cold room control, ensuring optimum performance in any situation under the most demanding conditions.

Eliwell Ibérica's Coldface series is the ultimate solution for cold room control in the HORECA sector.

Coldface 300NT, 500NT and 5000NT Highlights

- Integral Management of the Refrigeration Chamber

- A single device is sufficient to manage all the functions of a refrigeration chamber, whether static or ventilated, facilitating operation and maintenance.

- Installation Versatility

- These devices allow the installation of a power contactor or a circuit breaker inside, offering flexibility and adaptability to different needs.

- Space for Electrical Apparatus

- Coldface models have additional space to accommodate other appliances or electrical equipment, optimizing the use of space and simplifying component management.

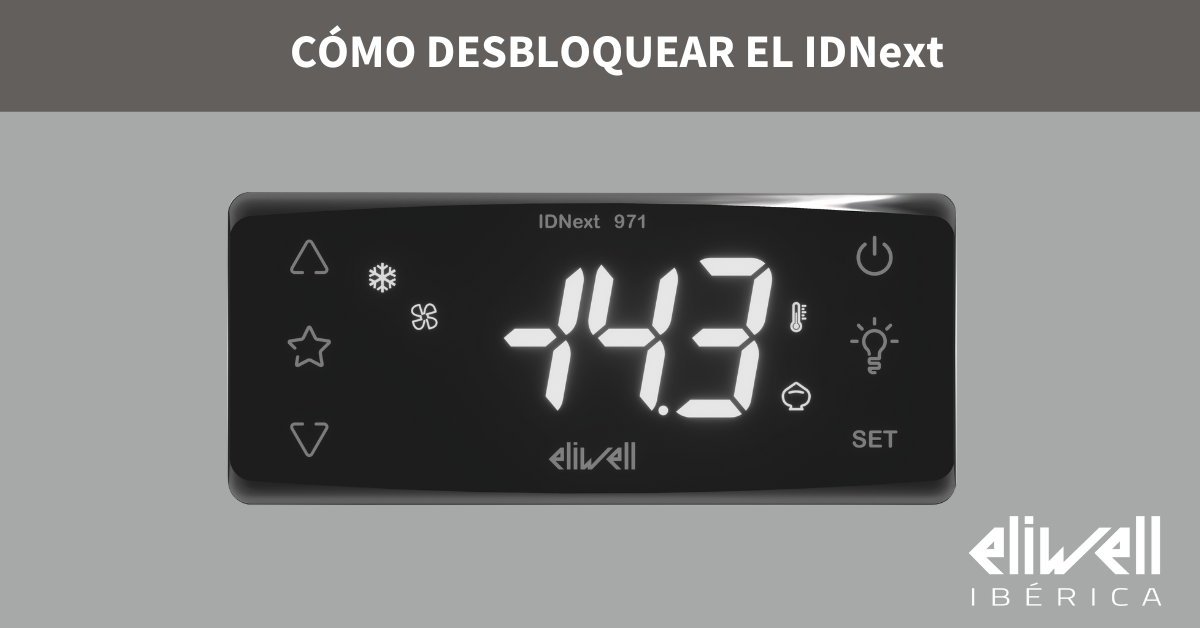

- Double Display with Luminous Icons

- The dual display with illuminated icons provides a clear and easy-to-interpret visualization, enhancing interaction and control of the system.

- Direct Access Keys

- Four large keys allow direct and quick access to the most frequently used functions, improving operational efficiency.

- Specialized Models

- The 4D model is ready to install circuit breaker protection, while the W/B model already includes 16A circuit breaker protection, offering specific solutions according to the user's needs.

- Strength and Functionality

- Water resistant, ensuring durability and optimal performance in demanding environments.

- HACCP function for food safety control, ensuring compliance with sanitary standards.

- Day/night function and Pump Down function for efficient energy management and maintenance of ideal cooling conditions.

- Ample Space for Power Elements

- The EWRC 5000NT offers ample interior space for three-phase switchgear, facilitating the installation and maintenance of more complex systems.

Configuration and temperature recording from the bluetooth dongle or remote management system such as compact touch or box remote management system such as compact touch or box

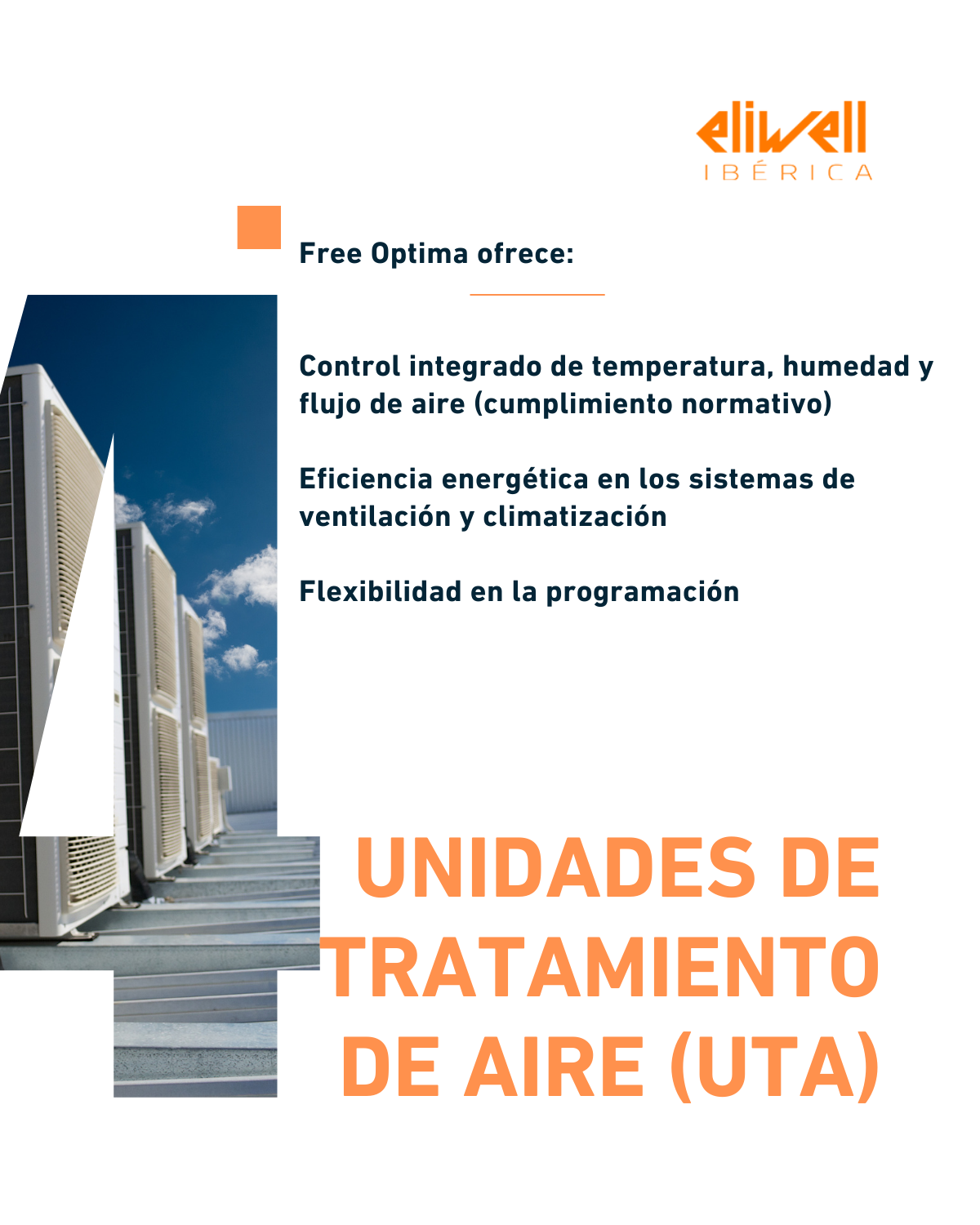

Helps to comply with regulations with accessories

Benefits for the HORECA Sector

Eliwell Coldfaces ensure that your products are kept at the right temperature, avoiding economic losses and protecting the reputation of your establishment.

For more information about the Coldface 300NT, 500NT and 5000NT models, and how they can help your business, contact us today at comercial@eliwell.es or sat@eliwell.es or 96 313 42 04.