We will guide you towards the energy efficiency required by RITE

The new RITE regulation has arrived, and with it, the demand for more efficient and sustainable buildings. Are you ready to adapt? At Eliwell Ibérica we offer you the integral solutions you need to comply with the regulation and transform your building into a model of energy efficiency.

The RITE challenge

The RITE (Regulation of Thermal Installations in Buildings) requires the modernization of thermal installations in buildings to reduce energy consumption and pollutant emissions.

This involves implementing control and automation systems, monitoring energy consumption and optimizing equipment performance.

Failure to comply with the regulations can lead to significant financial penalties, can result in the stoppage of the activity and the impossibility of obtaining permits or licenses.

Entry into force: Are you ready for the new regulations?

The RITE is in force since its publication in the BOE, but there are specific deadlines for the adaptation of existing buildings depending on their characteristics. It is essential to check the deadlines applicable to each type of building and installation according to the regulation, summarized in the following timeline.

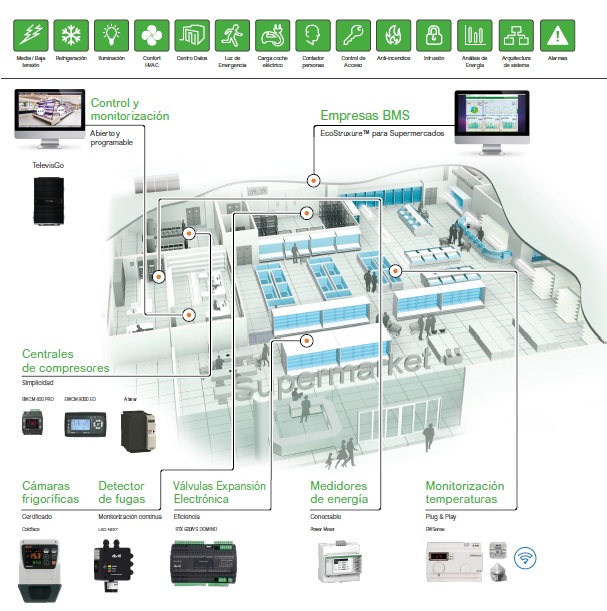

The Eliwell Ibérica BMS solution

We offer you a wide range of solutions designed to meet the RITE requirements and optimize the energy efficiency of your building:

Building Management System (BMS) is the comprehensive solution for the control, monitoring and management of all systems in your building (HVAC, cooling, lighting, etc.).

The BMS allows you to :

Automate processes and optimize equipment performance.

Monitor energy consumption in real time and detect inefficiencies.

Generate detailed reports for regulatory compliance and decision making.

Integrate different building systems into a single platform.

Electronic controls for refrigeration and air conditioning: A wide range of electronic controllers designed to optimize the performance of your refrigeration and air conditioning equipment. These controls allow you to:

Smart thermostats: Programmable and connected thermostats that allow you to control the temperature of your building remotely and optimize energy consumption.

Thermal and electrical energy meters: Accurate and reliable meters that allow you to monitor the energy consumption of every piece of equipment and system in the building.

Advantages of choosing Eliwell for building efficiency

Our solutions are designed to comply with RITE requirements and avoid financial penalties. We open the door to significant energy savings, optimizing the performance of your equipment and reducing energy consumption by up to 30%.

We promote a more comfortable and healthy environment for building occupants.

And you can recover your investment in a short time thanks to energy savings and reduced operating costs.

Always with the close assistance of our technical support.

It is our hallmark that defines us as a company. For this, we have a team of experts who will provide you with the technical support you need throughout the implementation process.

Contact Eliwell Ibérica today and find out how we can help you comply with RITE and transform your building into an energy efficient model.