How do I mark my cold room to make it legal?

Acoustic and light signaling in cold storage rooms is crucial to ensure safety in compliance with current regulations in Spain

Eliwell thermometers and recorders are metrologically certified and comply with data logging legislation for refrigeration systems.

The IF RD 552/2019 regulation on cold storage facilities highlights the importance of proper signage in cold rooms to ensure safety and regulatory compliance.

The acoustic and light signaling in cold storage rooms is specially contemplated in the regulations. And when we talk about these requirements we refer, among others, to the fact that the facilities must have refrigerant leak detection systems that activate an audible and visual alarm in case of detecting dangerous levels of gases.

Safe cold rooms with acoustic and audible signals

In addition, the cameras should be equipped with alarms that are activated in emergency situations to alert personnel inside the cameras. In this line, it is of vital importance the emergency stop buttons that must be located both inside and outside the chamber and when activated, they must emit an acoustic signal.

In this post we detail all the signaling elements and equipment that Eliwell Ibérica advises you to use so that your cameras operate efficiently and in accordance with the law, minimizing risks and legal responsibilities in our country.

The implementation of these signals not only improves safety, but also optimizes the operational management and maintenance of refrigeration facilities.

Eliwell complies with cold storage room signage standards

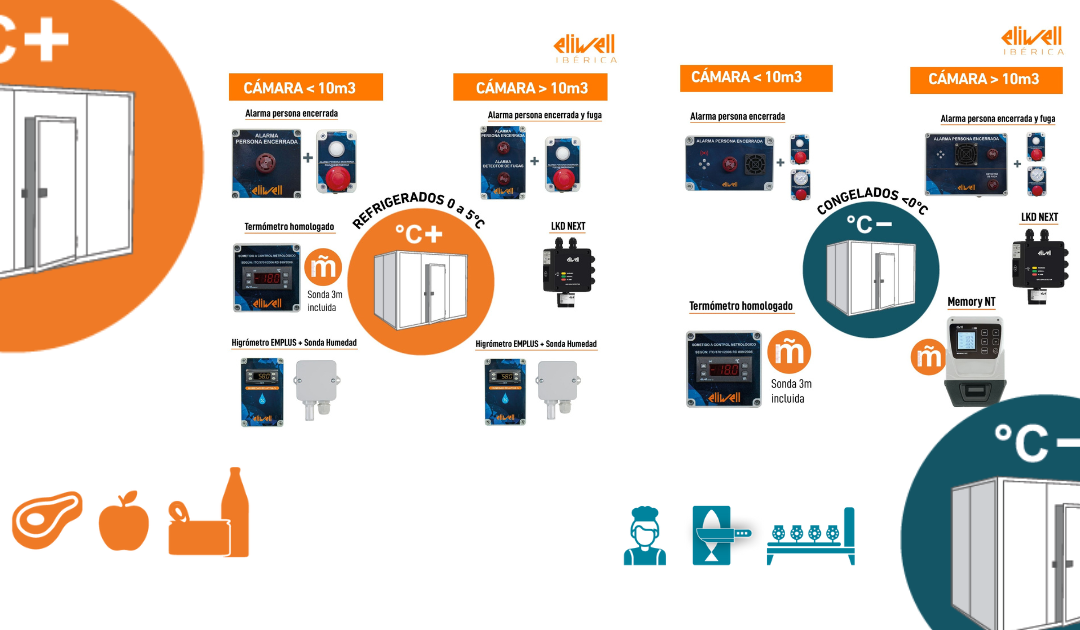

We begin the review in a graphic, easy and brief way of what the regulations require for the signaling of cold rooms both in refrigerated chambers, those of positive temperature from 0º to 5ºC, negative or frozen chambers below 0ºC and in bakeries and machine rooms.

Eliwell equipment for refrigerated chambers

For cold rooms operating in a range of 0º to 5ºC some of the mandatory equipment includes refrigerant leak detection systems, adequate ventilation devices, safety signage and regulated temperature controls.

For positive chambers smaller than 10 cubic meters we recommend:

- Simple locked-in person alarm plus emergency push button

- Approved thermometer metrologically certified. It will read and record twice a day and it must be recorded in documents. Includes 3m probe

- Easy to read and calibrated hygrometer or EMPLUS V/I for unpackaged perishable products. With probe to record humidity. A hygrometer is a simple tool used to measure humidity in the environment, generally in terms of relative humidity, which ensures the preservation of products and goods.

For positive chambers larger than 10 cubic meters, it is exactly the same equipment as just described plus a leak detector when the refrigerant concentration may exceed the practical limit, we recommend the Eliwell LKD Next. The maximum area that can be monitored by a single probe should be about 50 m2.

In the following diagram, we graphically represent the signaling for cold rooms in compliance with the regulation of refrigeration installations with Eliwell Ibérica equipment.

Eliwell equipment for frozen storage

For cold rooms operating in a range below 0ºC, we list below the necessary equipment that complies with the regulations in force in our country regarding signaling and registration of this type of refrigeration installations.

For negative chambers smaller than 10 cubic meters we recommend:

- Locked person alarm with or without battery

- Approved, metrologically certified thermometer

For freezing chambers larger than 10 cubic meters, it is required:

- Locked-in person alarm and escape

- Temperature recorder, we recommend the Eliwell Memory NT as it is metrologically approved.

- Leak detector, we suggest the Eliwell LKDNext when the refrigerant concentration may exceed the practical limit.

Once again we show you graphically all the elements necessary to comply with the regulations. Our safe bet with Eliwell equipment would be reflected in the following schematic for freezer rooms.

And, finally, our review of the signaling regulations for cold rooms in compliance with the Regulation of refrigeration installations (IF RD 552/2019) ends in the bakeries and machine rooms.

This category can be divided into single gas leakage signaling or when two gases converge to better reflect which equipment is required in each mode.

Thus, for this type of single-gas refrigeration installations it is required:

- Refrigerant leak detection alarm

- And a leak detector such as Eliwell's LKDNext

For two gases the same as above is required, but with the following peculiarity:

- Double leak detection alarm

- One LKDNext Leak Detector for each gas.

The following chart shows the equipment that we at Eliwell Ibérica recommend to comply with the regulations on signaling in compliance with the Refrigeration Installations regulation.

In conclusion:

It is essential that all these facilities are properly maintained and undergo regular inspections to ensure their safe and efficient operation in compliance with established regulations.

For specific details, please refer to the full text of the regulations. IF RD 552/2019 and the guides provided by official agencies on the web site of the Ministry of Industry - Refrigeration Installations (COIIIAO). However, to ensure that all signs comply with the relevant regulations, it is advisable to consult a safety expert and follow the guidelines provided by the applicable regulations.

Eliwell Ibérica can help you directly in this matter. Do not hesitate to contact us.

supermarket located in San Bartolomé de Tirajana has installed the R134a /CO2 hybrid solution.

supermarket located in San Bartolomé de Tirajana has installed the R134a /CO2 hybrid solution.